FSU College of Fine Arts News

Zachary Payne works with Associate Professor Jacki Armit on a piece for “Dragons Love Tacos” in 2022. Three students from the Florida State University School of Theatre’s MFA costume... READ MORE »

Conservatory production of Romeo & Juliet 2024, Photo by Frank Atura Sarasota, FL – The FSU/Asolo Conservatory for Actor Training in Sarasota is pleased to announce a transformative contribution... READ MORE »

Works by six Florida State University studio art graduates are on display at New York City’s famous Pen + Brush Gallery as part of a group exhibition honoring Women’s... READ MORE »

Sara Shelton Mann and Jesse Zaritt Legacy Artist Sara Shelton Mann and her collaborator, Jesse Zaritt, came to MANCC earlier this spring semester to further develop their body of... READ MORE »

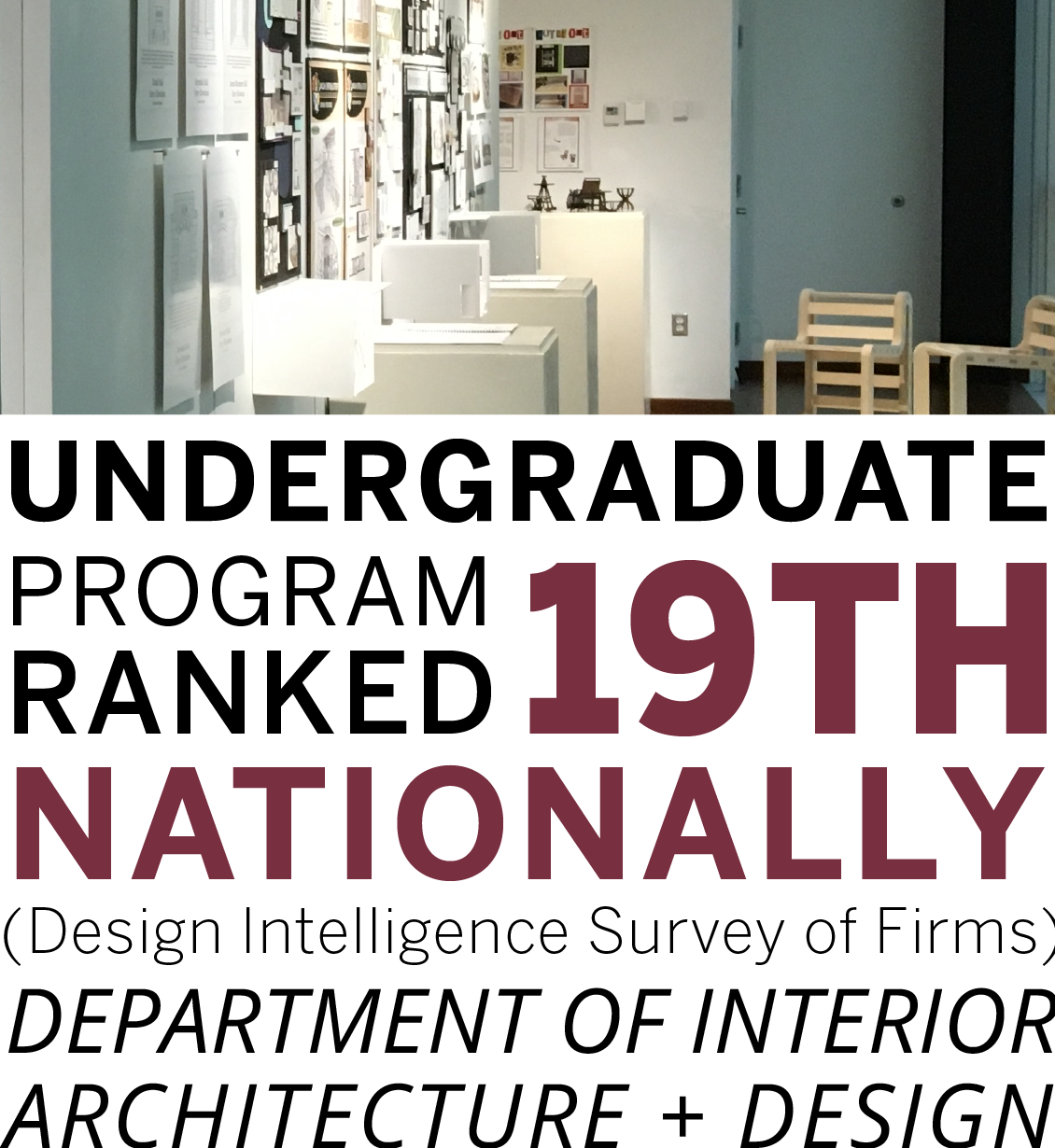

The Florida State University Department of Interior Architecture & Design celebrated its 5th annual alumni awards READ MORE »

A former graduate student of Florida State University’s Department of Art History is now the Tibbals Curator of Circus at The John and Mable Ringling Museum of Art’s Circus Museum and is... READ MORE »

More News »